If you are considering buying or leasing a printer or photocopier, there are lots of different things to consider. There are many types of machines available in the market at the moment, most with very similar standard features, however an abundance of the more modern products, have fully bespoke and unique features. This section of the guide will aim to clarify how they differ.

3.1 Types of Printers and Photocopiers

All-In-One Printers – Home Office Printers and Photocopiers

Home office printers and photocopiers are typically smaller in size, meaning they are able to fit into the smallest of home offices or studies. They are usually designed for a lot less use and therefore tend to have a lot less features – typically they do not print or copy in higher volumes or at extra fast speeds. The home office printer or copier is ideal for families, or home workers that do not print a lot or require additional technology features, such as network connectivity.

Desktop Printers and Photocopiers

Desktop Printers and Photocopiers

Desktop printers, like home office printers, are generally smaller in size in order to enhance office space utilisation. Desktop printers are compact and quite literally sit comfortably on a desk top, increasing available floor space. They are ideal for small teams that need constant access to a printer or copier. For small teams that want to be able to have more functionality, without using up valuable office space, desktop photocopiers allow users to print, copy and scan.

For small teams that want to be able to have more functionality, without using up valuable office space, desktop photocopiers allow users to print, copy and scan.

See our range of desktop photocopiers

Floor-standing Printers

Floor-standing printers, also known as office printers take up more space than desktop machines, however their benefits usually outweigh the space they use for most businesses. That being said, they do come in different sizes, so there are options for choosing a printer to suit the available space. Floor-standing printers are capable of near constant and consistent printing. Office printers are able to print on a variety of paper size, including A3 paper due to the machines larger paper storage space.

Floor-standing Photocopiers

Similarly, to floor-standing printers, these copiers take up a larger space than their more compact desktop photocopier counterparts, but you can typically pick a machine that suits the space. Bear in mind however that the larger the print dimensions you need then the larger the machine will be. Floor-standing photocopiers, or office photocopiers, are multifunctional devices, providing print, copying, scanning, email, and faxing facilities, making these machines ideal for organisations that require more than just basic print capabilities.

Multifunction Printers

Multifunction printer is an alternative name for a modern day photocopier. Multifunction printers have much better specifications than standard printers. They are typically larger and floor standing in order to accommodate for the additional features. Multifunctional printers normally allow you to print in different sizes, print in colour or mono (black and white), print from different devices, fax, scan, copy.

Digital Press

In the past five years, digital press machines have become cheaper and have developed more advanced capabilities. It is for this reason that companies are increasingly using digital print machines, bridging a long-time gap in the market, and allowing organisations that need light duty print capabilities to do so in-house. Also known as light production, these devices are typically very fast and an exceptional print quality. These machines are ideal for companies that wish to print high quality documents at superfast speeds, but with added finishing options you would normally associate with outsourced printing. Digital presses are normally found in reprographics departments, and can print thousands of sheets per day.

Production Printers

Heavy duty, or production printers are designed for much more than digital presses. Production machines are capable of printing more complex print items such as manuals and booklets at a very high speed. These machines tend to start at around 60 pages per minute (ppm) however some vendors will contend that such printers must produce 100 – 150 ppm to qualify in this category. These machines appeal to companies that want their printed materials ready to go once printed; this can include many advanced finishing options, such as: lamination, many types of folding, trimming and even additional colours (printing in a 5th ink) – see internal finishing features.

Large Format Printers

Large format printers, also known as wide format printers, plotters, and LFPs are designed to print larger items such as banners, posters, trade show graphics, wallpaper, murals, and vehicle image wraps, to name a few. These machines typically use some form of inkjet technology, and therefore tend to be more economical than other print methods as very little to no heat is required to fuse the ink to the paper. Large format printers also usually print onto a continuous roll of varying print media, such as tracing paper, film, vinyl, and photo papers, to name a few. Large format printers can therefore be used in many different industries such as:46 print production, photography, construction, and advertising industries, and because they can print on a continuous roll, they print quickly and efficiently. Paper size should be considered with large format printers however, as smaller machines will not be able to deal with thicker or larger paper.

Risographs (RISO)

The Risograph, also know as a RISO duplicator is a high-speed digital print system manufactured by the RISO Kagaku Corporation for high-volume copying and printing, sometimes referred to as a duplicator. When copying, the original document is scanned and the ‘master’ is created, the master is then wrapped around a drum with ink being forced through tiny voids in the master. The Risograph is ideal for organisations that wish to print near-constantly and consistently. Paper also runs flat through the machine, meaning they have a very low risk of paper jamming, especially because they do not use heat to dry the finished print. This also means that they are much more reliable than many other printers that use other traditional print methods.

The Risograph can normally only print in a single colour at a time, allowing it to print high volumes at speed. However, the company has developed the RISO MZ Series, which consist of two internal ink drums, allowing for two colours to be printed in one pass. Some Risographs have also been developed with finishing features, such as binding and stapling, allowing them to be used in production printing.

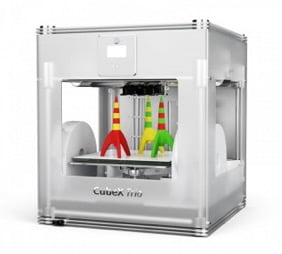

3D Printers

3D printers or ‘additive manufacturing’ is a process whereby a printer creates a three-dimensional solid object from a digital code. The object is printed from an additive that is set in layers until the object is created. Some 3D printers use melting or softening of materials to produce these layers. As with conventional paper printers and photocopiers, a 3D machine can come in varying sizes, but most are quite large in order to accommodate the size of objects that industries and consumers wish to create. Within commercial markets 3D printers are typically used to rapidly produce prototypes before mass production of the actual product.

3.2 Types of Printing Processes

Lithographic Printing

Lithographic printing, or lithography, was invented in 1796 by German author and actor Alois Senefelder, and is a type of printing that derives from the immiscibility of oil and water. The technique uses simple chemical processes to create an image or print. For example, the positive part of an image is made from a hydrophobic substance, whilst the negative parts of the image would be hydrophilic. So, when the plate is introduced to a compatible ink and water mixture, the ink will stick to the positive sections of the image, and the water will clean the negative parts.

Lithography is an extremely popular printing technique today, and is widely used in professional printing, outsourced printing, and as an art form.

Digital Printing

As technology has progressed at an increasing rate within the print industry so has product innovation. There were many types of print processes that predated digital print, these were typically: cumbersome, inefficient, and time wasting. However, such processes have subsequently been replaced by computer procedures and software. Digital printing processes have therefore been developed in order to optimise print machines, and tend to be a lot quicker than traditional print processes. One major reason for their efficiency is because the ‘printing plates’ within machines do not need to be replaced, whereas analogue printers need these plates repeatedly replaced. There are two main ways in which digital printing is used today – laser and inkjet.

Laser Printing

Laser machines can produce higher-quality prints, by repeatedly passing a laser beam back and forth over a negatively charged ‘drum’ (a light-sensitive rotating cylinder) in order to define a positively charged print layout. The drum will then collect electrically charged toner (powdered ink) and transfer it to the print medium. This is then heated and fuses the toner to the page.

Laser printers and photocopiers are a digital printing process that uses static electricity. They were invented at Xerox Parc in the 1970s, first being introduced for home and office markets in the following years by corporations such as Xerox, Canon, Hewlett – Packard, and Apple. Laser printers are now widely used all over the world, with quality and speed improvements increasing as the price of the technology has decreased.

Inkjet Printing

Inkjet printing uses propelled droplets of ink in order to create prints and copies, with the print layout being determined by computers. The ink droplets can either be left to dry on their own, or some machines will gently heat the paper in order to speed up the process. Inkjet printing is normally considered to be the cheapest method of printing, as it requires little to no heat for the ink to dry, whereas laser printers require heat to fuse toner powder to the page. Inkjet printing also reduces environmental impact and is popular with large corporates that encourage environmental preservation within their company culture.

Geljet Printing

Geljet technology was developed by Ricoh in order to optimise the print process. Gel ink is passed from vacuum-packed ink cartridges by way of a two-tank system. Each gel colour is pumped through a hollow cylinder to a reservoir within the print head. The reservoir is filled up whenever gel ink levels fall below a certain level in order to guarantee that ink supply is constant and produces no waste. GelJet printers use a ‘micro-piezo system’ whereby a small part in the nozzle of the print head is charged with electricity, the part then restricts or distorts. This causes pressure to build up in the nozzle, which in turn forces the gel to be projected from the nozzle and onto the print medium. GelJet technology is far more controlled than typical ‘bubble’ technology used within inkjet printers. This technology heats ink, making it form bubbles, which are then squirted onto the paper. This sometimes causes blotches and smudges. Therefore, GelJet machines are essentially a hybrid of both inkjet and laser technology, and can make a huge difference to any office or organisation.

3D Printing

3D printing or ‘additive manufacturing’ is the name given to a process that prints successive layers of material, via computer control, as a three-dimensional object. Early forms of 3D printing were developed in the 1980s, today, 3D printers are used for product development within many industries, particularly to create prototypes before mass production by printing with plastic, metals, or even chocolate. The print method is only just starting to enter consumer markets due to reductions in technology costs.

3.3 Standard Machine Features

Mono

Mono, when referring to colour, is defined as ‘having only one colour; monochrome,’ or ‘a representation in one colour.’ Within the print industry, this is usually taken to mean printing in black and white, but some industries use mono to describe printing in any singular colour, and white. In photography and imagery, the term can be called greyscale, which views black and white printing as varying shades of grey.

Colour, CMYK, Colour Gamut

Colour printing refers to the printing or reproduction of an image or text in colour as opposed to the much simpler black and white, or monochrome printing. Outside of print, the three primary colours, red, green, and blue, can be specifically dissected to give the visual sensation of all other colours.

The CMYK colour model is used in colour printing and refers to the four inks used in most machine: cyan, magenta, yellow, and key (black). Black is referred to as key because when the cyan, magenta, and yellow plates align they slot into the ‘key’ of the black key plate. The CMYK model is what is known as a subtractive colour model, as ink is applied to the paper and reduces the light that would otherwise be reflected – ‘subtracting’ the brightness of the white.

Colour Gamut refers to a colour space, or the complete subset of colours, that are able to be displayed on a particular device, for instance a monitor. A screen monitor, which uses the RGB (red, green, blue) colour model, usually has a greater colour gamut than a printer which uses the CMYK inks. ‘Out of gamut’ means when colour cannot be converted from one device to another, for example one printer to another.

Simplex

The term simplex printing essentially means printing on one side of a page. Simplex printing deposits the ink or toner to the print medium in one pass. Printing on two sides is possible in a simplex machine, however ink and toner can leave marks throughout the machine that could compromise future prints. You will also have to manually put the paper back into the machine once one side has printed, and flip it, so if quick printing is desired then a machine with duplex printing capabilities may be more suitable.

Duplex

Duplex printing is a feature of some print machines and multifunctional devices that allows for the printing on both sides of a print medium. Most of these machines print on one side of a page, reverse it, and then prints on the alternate side to produce the two-sided print. Devices that are designed to print in higher volumes can have two print heads that relay the ink or toner in one pass, making these machines useful for organisations that wish to print quickly.

Contact us Contact us if you are in need of a new Photocopier

3.4 Copying

Photocopying is a technique used by photocopiers and multifunctional devices that reproduces an original paper document quickly and cheaply. Most of these machines use a technique called xerography, which is a dry process that uses electrostatic charges on a light-sensitive photoreceptor to attract and then transfer toner particles onto the paper.

Editing from the Photocopier

Digital photocopiers are so advanced today that they can edit documents during the scanning and copying process. For example, an image or text could be enlarged or reduced in size from the photocopier control panel, or made brighter or darker, as opposed to altering your prints from a computer. Other types of editing are available, including: page numbering and automated annotations, watermarks such as ‘confidential’, adding cover pages and inserts, or adding date stamps. These functions can be highly useful when it comes to organising business documents.

3.5 Scanning

Scanning is now a necessity for any organisation. With the basic function of the scanner being able to analyse an image, process it in one way or another and output it in varying sizes, options and file formats. As with printers and photocopiers, scanners have become a vital office technology that is widely used.

Similarly, to other office machines, scanners also come in varying sizes and capabilities, even performing with different internal mechanisms.

Types of Scanners

Sheet-fed scanners are simple, they require the user to insert the document to be scanned into a loading tray, and the machine moves the document and scans it internally.

Hand held scanners require the user to move the scan head over the document themselves; this type of scanning does not normally produce a good quality image but is useful for quickly capturing bodies of text.

Another type of scanner is the drum scanner; a method of scanning that is traditionally popular with publishing houses in order to capture very detailed images. Within drum scanners, photomultiplier tube technology mounts paper onto a glass cylinder that splits light bounced from the scanned document into three coloured beams. Each of these beams is sent through a filter where light is transformed into an electrical signal to produce the print.

The most commonly used type of scanner technology is the flatbed scanner. This type of scanner simply requires the user to place the document to be scanned onto a sheet of glass, under a lid; light is then passed down the document and fed back as code to then be printed. This type of scanning is useful if you do not need to print several documents at once, if a lot of pages need to be scanned then a sheet-fed scanner would be more useful as the machine can scan a pile of inserted documents by itself.

Scanner Technology

There are also many additional scanner functions coming to the fore as a result of modern advancements in technology. Developments made in personal devices such as mobiles have meant that scanners have had to keep up. It is for this reason that scanning to email, network, a particular folder, desktop, or memory stick are now widely available on many scanners or multifunctional printers. These modern features increase connectivity, security, and work flow, so any good machine should include these features in the modern day for the modern business. On modern-day photocopiers and multifunctional printers, scanning a document will result in a copy of it being stored on the machines hard drive, alongside any copy or print. Users should be aware that this information is saved to the device for future security reasons.

3.6 Faxing

Faxing can be an important and useful tool for many organisations. Fax machines use a telephone line as a communication function between machines; they send scanned original documents and receive data sent from other machines. The telephone line will be connected to a printer or other output device with printing capabilities. The sent items are converted to a bitmap, (a type of memory organisation or image file used to store and transport digital images) and then transmitted through the telephone line as audio frequencies. The receiving machine interprets these frequencies and re-pieces the job, printing a finished paper copy.

Faxing Technology

Alexander Bain, a Scottish inventor who was able to reproduce graphic designs in his initial laboratory experiments, invented the early fax machine; he eventually received a patent for his ‘Electric Printing Telegraph’ in 1843. It was not until 1924 however that the modern and compact fax machine was created by the AT & T Corporation, where it entered mass markets due to the small office space it required and the simplicity of its function.

The Future of Faxing

Faxing today is seen as a dying business system, as the dawn of the Internet has made printing and scanning much quicker and easier than faxing. The adoption of new IT devices such as smartphones and tablet technology, has resulted in information becoming so much more accessible, making faxing a some what redundant technology. However, the countries where electronic signatures on contracts are not yet recognised by law still require the use of fax machines within business. Faxing therefore, at least in business, is something that is becoming incorporated within multifunctional printers and photocopiers as opposed to machines with only faxing functionality.

3.7 Additional Machine Features

Document Feeder

In a multifunctional device, a document feeder allows the user to scan, copy, print, or fax multiple pages at once, removing the need to continuously add and remove single documents.

There are typically two types of document feeder that can scan on both sides (duplexing). A duplexing automatic document feeder (RADF), which scans one side of a document and then flips it to scan the other side, or a duplexing automatic document feeder (DADF) which scans both sides in one pass.

Colour Matching

In order to understand colour matching, it is first important to understand the different ‘colour spaces’ or colour pallets used by printers and photocopiers. There are two colour spaces that are typically used in technology in order to maximise the colours they can either be viewed or printed in. RGB (Red, Green, Blue), typically used by screens, and CMYK (Cyan, Magenta, Yellow, Black), generally used by print machines. Another system, the Pantone Matching System (PMS), provides 1,114 colours and provides each colour with a code, ensuring that users of such colours can use the exact colour next time they use it, and not a slightly different shade. Today, digital printing devices do not have to be restricted to a single colour space like older more traditional CMYK machines do. Many of these newer machines can now print RGB and Pantone files by converting the colours to CMYK – this is called colour matching.

Mobile and Tablet Printing

Another, more recent technological advancement in printing is being able to print from devices such as mobile phones and tablets, all whilst on the go. Mobile printing allows you to use a printer from anywhere, giving employees the ability to go wherever their business takes them, whether it’s printing from home to work, from office to office or at a client’s premises; this can now all be done by installing specialist mobile printing apps. Built-in security features usually make documents secure and allow only you to print them. Virtual spaces such as ‘the cloud’, can also help organisations move towards the use of mobile printing, as they eliminate the need for expensive desktop hardware such as computers.

Contact us Contact us if you are in need of a new Photocopier

3.8 Internal Finishing Features

Printers and photocopiers can come with additional features that help to finish your prints; this is sometimes referred to as internal finishing equipment. These functions can come as standard on some printers and photocopiers; however most machines will require these features to be added as attachments to the machine.

Booklet Printing

Booklet printing is an advanced capability of some duplex (double sided) printers and photocopiers that allows for the production of print items that are not available with standard printers. This function can help organisations with constructing finished booklets and brochures of different sizes and thickness. The paper or other print medium is fed into the machine where pages are input as one-sided or two-sided and output so that they are printed in order and automatically folded. Booklet printer functions such as saddle stitch stapling can be incorporated as an additional and optional extra, automatically binding items such as booklets together.

Sorting Trays

There are two main sorting methods used by printers and photocopiers, sorting trays and electric sorting into a single tray. Sorting trays are a series of mechanical trays located at the output end of the printer or copier, simply, they allow for the collation and organisation of documents into groups. They are particularly useful for organisations that have deadlines, such as healthcare and religious institutions, and therefore do not have time to sort through printing themselves, particularly if prints need to be sent to different locations quickly. It is also quite common to see other finishing functions alongside sorting trays, such as stapling.

Electrical sorting functions are slightly more complicated to understand but achieve the same end result. This sorting function does not use several sorting trays; instead documents are fed into one tray at the output end of the machine at a right angle, or by shift sorting so that groups of pages are easily recognisable and distinct from each other. This sorting function is normally seen as better than the multiple tray alternative as it requires less space to deploy, and also allows for unlimited sorting, rather than being limited to the number of sorting trays.

Stapling and Hole Punching

Finishing equipment such as stapling or binding and hole punching functions can also be a hugely useful addition to organisations using printers and photocopiers. There are many stapling options available today, such as top left or centre edge for example, both of which can be incorporated into many printers and copiers by bolting an extra unit onto your machine. Binding such as saddle stitch is also available here, which uses a metal or plastic circular strip to bind documents at the spine.

Hole punching is another useful advanced function of many printers and copiers. Hole punching is available in any number required, including two and three holes. These internal finishing features can save vast amounts of time and effort for a time conscious business. Hole punching capabilities can be particularly useful for businesses that file lots of documents in folders, such as ring binders for example.

Binding

Binding refers to the act of collating sheets of paper and fastening them together to make books, booklets, or leaflets, to name a few. Although binding is viewed as a post-print function, it has to be considered in the pre-print phase. There are several basic means of binding sheets together including: case binding, mechanical binding, perfect binding, saddle-stitch, and strip binding.

Case Binding

Case binding, or thread sewing, involves stitching a book together by means of thread or cord often with an adhesive, ensuring that it is extra secure. The thread is passed through back folds in the document spine, allowing the book to lie flat once finished.

Mechanical Binding

This is the most basic binding technique, and typically involves fastening pages together with plastic teethed combs, wire, plastic coil, or holding pages together in ring binders. The term mechanical binding comes from the practice of drilling the holes in the stacked pages with machines, which the fastening tools can then be slotted through.

Perfect Binding

Perfect binding, or adhesive binding, means the fastening of pages to a spine or cover with glue. After the sheets are gathered, a gluing device applies a thin film of adhesive to the edge of the pages, where they are then secured onto the spine to form the document or book. Common examples of this technique can be seen in paperback books, magazines, and telephone books.

Saddle-Stitch

Essentially, saddle-stitch binding involves the use of wire staples to fasten pages together. These staples are driven through the centre of the document spine once folded. This type of binding is frequently seen in the form of newsletters and magazines.

Strip Binding

This type of binding is perfect for legal briefs, transcripts or financial reports as they are easy to mail and file due to the sleek nature of the fastened edge. In strip binding, the stack of pages are secured together by joining plastic or metal strips through punched holes.

3.9 External Finishing Equipment

As with printers and photocopiers, there are many different types of external print finishing equipment available. Finishing equipment gives users more options, flexibility and creativity over the documents they can produce themselves in-house. External finishing equipment simply means it is external to the main engine of the printer or photocopier, some of the more common external finishers are covered below.

Hole Punches

A hole punch is a common office tool that is used to create holes in sheets of paper, normally to allow the sheets to be collected and filed in binders and folders. A typical hole punch, once paper is inserted, has a long lever which is used to push a sharp metal cylinder through the inserted sheets of paper. Two sliding paper guides are normally needed to help line up the paper accurately. Another mechanism exists that uses drills, which are lowered in a screwing action into the paper to produce a hole.

Hole punches also come in varying numbers of holes required. The most common standard for the dimensions and location of holes punched is two holes; also known as International Standard ISO 838. A four-hole extension is also commonly used. The two middle holes are punched in accordance with ISO 838, meaning they can also be filed in standard folders and binders. The use of the two extra holes is sometimes referred to as ‘888’ and provides much more stability than the standard two holes. Hole punches can also come in 3 hole and single hole variations.

Staples

A staple is a type of two-pronged metal fastener, used for binding materials together. Large staples might be used with a staple gun for heavy-duty uses, such as roofing. The more common smaller staples are used with a stapler to join sheets of paper together; staples are therefore a more secure method of attaching paper than other mediums, such as paper clips.

Staples are commonly used at home due to the neat and secure nature of the finished final product. They are also widely used in business because of their relatively minimal cost, availability, and their small appearance does not take away from the content and purpose of the document.

See more about the function of a photocopier

3.10 Other Considerations

Size and Dimensions

While examples of machines and industry specific considerations have been mentioned, there are also other things to be considered. The size and dimensions of machines are an important one of these contemplations as office space may not be ideal for the size of machine required. Obviously if advanced printing needs are not required, then a small and robust machine would be fine. However, if advanced machines and features are required, the need to print in larger formats or volumes, then this should be taken into consideration when examining the space available. Paper size usually affects printer size, so the smaller desktop devices typically print in A4, floor-standing photocopiers and multifunction printers and digital presses can print A4 and A3 and then large-format printers can print up to A1 and even A0 paper sizes.

Print Speeds

Print speeds are also a key additional consideration. If print speeds are minimal, for example you just need a machine to print on occasion, then a compact and reliable machine that does not require much attention may suit. However, some organisations require high volume printing at speed, meaning faster more expensive machines should be considered.

Print Drivers

Print drivers are communication layers of code that translate between computers and printers. One of the main functions of a print driver is to transform text and image data into printed materials. They are licensed, crucial elements for printers in order for them to communicate with other necessary pieces of office equipment, and reproducing an image from a PC identically onto paper. Once a machine has print driver software installed, it is very rare that you will ever need to renew the print driver license or contract; this is particularly useful information when it comes to buying a used device.

Print Command Language

Print Command Language, or PCL, is the name given to the language used between printing machines and computers as they ‘speak’ in different codes. PCL was originally developed by Hewlett-Packard for early inkjet machines in the mid 1980s and has now become the industry standard for regular PCs.

PostScript is a very similar communicative tool used between print machines and computers, however PostScript is able to translate between a much wider variety of computers and printers. PostScript was developed by Adobe Systems in 1984, and is a mainstay for many industries that need printers and photocopiers.

A bitmap (or raster) image refers to an image stored as a series of tiny dots, called pixels. Each pixel is essentially a very small square that is assigned a colour, and then arranged in a pattern to form the image.

A Raster Image processor (RIP) is a type of software that converts vector images into raster graphics or bitmaps. For example, a laser printer uses RIP software to convert images that arrive in vector form into raster images, making them printable.

A fiery raster image processor is a type of technology that comes in the form of an external box that is attached to a print machine. It is used to optimise and make changes to documents before the printing process.

Contact us Contact us if you are in need of a new Photocopier