RISO Duplicators – The Ideal Technology for Graphic Arts Printing

Originally designed to print high-speed documents for busy offices, schools and churches, RISO duplicators have found a new niche market in the field of graphic arts and design.

In recent years, we have seen a large increase in the number of commercial printers and university art departments investing in RISO duplicators. Also known as Risographs, these devices are the must-have tools for those interested in producing high-quality art prints, on a tight budget.

In recent years, we have seen a large increase in the number of commercial printers and university art departments investing in RISO duplicators. Also known as Risographs, these devices are the must-have tools for those interested in producing high-quality art prints, on a tight budget.

The machines use rich ‘spot colours’ which are ideal for creative graphic arts applications and can be layered to create the same affect as litho or screen printing.

RISO duplicators produce similar results to screen printing, but on a mass-production scale. So, designers can get the same results but much quicker,

as no time is required to prepare and clean equipment, pre-or post-printing. Not only this, but additionally the price per print is considerably lower.

RISO Inks

Like with commercial printing presses, RISO duplicators can build up layers of colour. However, rather than using levels of CMYK to produce process colours, RISO uses a spot colour-system similar to Pantones in litho printing, which means that the resultant colours are solid and more vibrant. The inks are not 100% opaque, so they can be layered to produce really interesting results. RISO has 21 standard inks, but when layered, thousands of colours can be produced.

There are many coloured inks that are unique to RISO, including fluorescent pink and metallic gold, which are impossible to create digitally and difficult through other print methods.

In a drive to meet continual moves towards environmental friendliness, RISO has developed a soybean ink for its duplicators. The ink dries instantly, without the need for heat in any aspect of the printing process, reducing the electricity consumption of the machine.

The RISO Printing Process

When sending artwork to print on a RISO, the documents should be set up as separations for each colour layer. Similar to how a litho printer will produce plates for each CMYK layer, but a RISO device can only print one colour at a time.

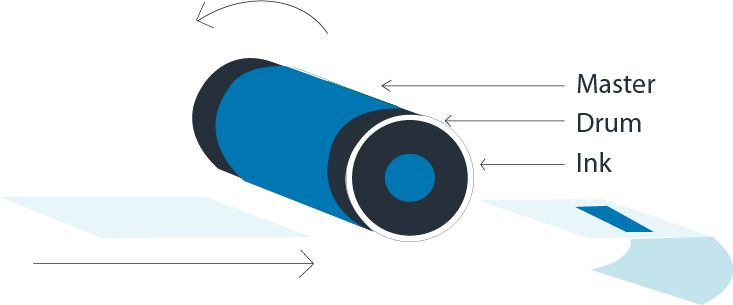

Risographs work by transferring artwork from a digital file onto a thick sheet of plant fibre material, known as a master. The master becomes a stencil, with little holes where the image should be. The master is then wrapped around a single-colour drum which rotates whilst pushing ink through the master onto the paper below. Multi-colour images are achieved by switching the colour drums and running the paper through again to over-print multiple layers, as you would when screen printing. Selecting an uncoated paper is preferable, as the ink needs to soak into the sheet, giving the best results.

An exciting development means that RISO printers can now print up to A2 in size, with the new RISO A2 duplicator being released in 2016. Unfortunately, as yet, they can’t print full-bleed, leaving a 5mm border around the edge of the sheet.

RISO duplicators were not originally intended to be used to create artwork using multiple colours, so the registration is not perfect. When producing prints with multiple layers, colour marks can be left though these are easily removed with a rubber. Often, this can add to final printed effect and adds even more character and originality to artwork, a popular by-product of RISO printing.

One drawback is that the machines struggle to reproduce type smaller than 8pt, and ideally text should be outlined to vector rather than being pixels, as the machine will produce a pixelated print if not.

Have a look at some designs produced by RISO duplicators

Have a look at some designs produced by RISO duplicators

Some of our customers that use RISO Printers to produce unique artwork include RISOTTO Press in Glasgow, HATO Press in London and Kingston University in London. Click on the hyperlinks above to look at their work.

Do you have a RISO duplicator that you use for printing graphic arts? We’d love to see some of your work. Tweet your photos to us @midshire!